When starting a new business that involves food and fresh produce you will undoubtedly need to purchase some commercial refrigeration. This area can seem quite overwhelming with so many different models, sizes, specifications and temperature ranges etc. Making sure that you make the right decision the first time may be a daunting task but a little time and research now will save you money in the future.

Commercial refrigeration can be very pricey and although your budget may be tight, don’t scrimp on your choice to save a few pounds. Your purchase will be what keeps your stock delicious and fresh and the old saying, ‘you get what you pay for’ has never been truer than when applying it to this area. By breaking down the fundamentals of commercial refrigeration and in particular, storage fridges and storage freezers and comparing them with your personal business needs and requirements, the choice you have to make should hopefully become a lot clearer.

Table of Contents

What Is Storage Refrigeration?

Why Buy Commercial Rather than Domestic?

Types of Storage Refrigeration

What Temperature Range Do I Need?

Measuring Sizes and Capacities for Storage Fridges and Freezers

Positioning and Placement

Cooling and Defrost Functions Explained

Specifications and Features of Solid Door Refrigeration

Getting to Grips with Refrigerants

Efficiency and MEPS

Cleaning and Maintenance

Choosing Your Warranty

When Will My Order Be Delivered?

Get Advice

What Is Storage Refrigeration?

Foster EP700H Single Door Catering Fridge

Foster EP700H Single Door Catering FridgeStorage refrigeration could easily be seen as the workhorse of the commercial kitchen. Recognised by the solid door design, this general term to used to categorise both fridge and freezer cabinets.

The primary function of this equipment is to hold and preserve foods and ingredients until they're required in the kitchen. Expected to hold precision temperatures with unwavering accuracy, these cold cabinets and freezer cabinets, unlike catering and cooking equipment, is always working. Very rarely turned off and given a break, it's vital to choose equipment that is up to the job.

Why Buy Commercial Rather than Domestic?

Although they may look similar to the untrained eye, there's a lot going on behind the scenes that differentiate commercial and domestic refrigeration. So what does commercial refrigeration have that domestic alternatives can't offer?

![]() Designed for regular use and frequent access unlike domestic. Even when subjected to repeated opening and closing of doors, units are still able to hold accurate temperatures.

Designed for regular use and frequent access unlike domestic. Even when subjected to repeated opening and closing of doors, units are still able to hold accurate temperatures.

![]() Built with added durability in mind thanks to higher grade materials and better build quality. This ensures that units can withstand the tough conditions of a working kitchen. Relating to both the materials used for the main structure and also in relation to the refrigeration components, both fridges and freezers manufactured for the commercial market are designed to work harder, improve consistency of performance and promote longevity of refrigeration.

Built with added durability in mind thanks to higher grade materials and better build quality. This ensures that units can withstand the tough conditions of a working kitchen. Relating to both the materials used for the main structure and also in relation to the refrigeration components, both fridges and freezers manufactured for the commercial market are designed to work harder, improve consistency of performance and promote longevity of refrigeration.

![]() Advanced precision and accuracy with regards to temperatures and storage conditions.

Advanced precision and accuracy with regards to temperatures and storage conditions.

![]() Better insulation not only helps with precision but also boosts efficiency.

Better insulation not only helps with precision but also boosts efficiency.

![]() Greater capacity to meet the storage demands of the largest operations.

Greater capacity to meet the storage demands of the largest operations.

![]() Ability to operate efficiently in higher ambient temperatures.

Ability to operate efficiently in higher ambient temperatures.

![]() Additional features that may not be available on domestic models such as locks, castors and gastronorm compatibility.

Additional features that may not be available on domestic models such as locks, castors and gastronorm compatibility.

Types of Storage Refrigeration

The broad category of Storage Refrigeration envelops a wide range of equipment, so there's plenty on the market to meet every requirement. Encompassing both fridges and freezers there are numerous layouts, designs and configurations to choose from.

Storage

Some storage refrigeration is intended for areas with an ambient temperature lower than 25°C. This will typically be a separate area away from the main heat of the kitchen.

Catering

Mercatus X6 Fish Keeper

Mercatus X6 Fish KeeperCatering models are suitable for operation in the high temperatures associated with a working kitchen that can reach as high as 30°C or 43°C. Single door catering fridges and double door catering fridges are available for chilled storage as well as single door catering freezers and double door catering freezers, all accumulatively guaranteeing that every refrigeration demand is met.

Learn more about the differences between storage and catering refrigeration here.

Fish Keepers

Other upright cabinets housed within the storage refrigeration category include fish keepers, manufactured with a protective coating that withstands the damaging effects of naturally occurring ammonia from the fish. Designed to hold a bed of flaked ice within every drawer, fish can be stored and preserved in optimum condition.

Undercounter

Undercounter storage fridges and undercounter freezers are categorised as equipment that measures less than 900mm in height, therefore can be positioned below existing counters. This is the perfect choice for businesses that want to make maximum use of all available space.

Tefcold UD2-3 Uni-Drawer Dual Temperature Gastronorm Counter

Tefcold UD2-3 Uni-Drawer Dual Temperature Gastronorm CounterDrawers

Introducing a variation from the typical tall, upright cabinet format, refrigerated drawers and freezer drawers offer an increasingly popular storage alternative, keeping chilled stock within easy reach during service. Manufactured with single, double or triple drawer models, as a chef base to support countertop cooking equipment or as a non-load bearing counter, drawers are versatile and energy efficient additions to any working kitchen.

Chest Freezers

Large capacity chest freezers can also be classified within the storage refrigeration genre, delivering unrivalled capacity and enhanced efficiency thanks to the chest design. To read more take a look at our Ultimate Buying Guide to Commercial Chest Freezers.

Roll-in cabinets are also available, ideal for large, high turnover kitchens that need to refrigerate or freeze in bulk.

What Temperature Range Do I Need?

The majority of storage refrigeration is suitable for general purpose use and as such will provide a wide temperature range to accommodate all stock. While fridges typically operate within a 0°C to 10°C range, freezers will hold sub-zero temperatures within a -10°C to -25°C bracket.

Some foods will require more specific temperatures in order to observe food safety and hygiene, temperature ranges that not all general purpose equipment may offer. This can be seen in the case of fish keepers and meat fridges. Observing precision temperatures within a -2°C to +2°C range for meats and a -1°C to +1°C range for fish, this equipment is designed specifically for purpose.

Measuring Sizes and Capacities for Storage Fridges and Freezers

One of the core decisions before making a purchase is to ascertain the size and capacity you need to fulfil your chilled storage needs. Size and capacity are closely related - obviously the larger the dimensions, the greater the capacity created.

There are multiple elements to consider within this area when choosing the right model for your business, some of them obvious others not so much.

It should be relatively obvious whether you're looking for an upright or undercounter layout, a straight forward decision that is easily assessed by the space you have available. Once this has been determined it's vital to accurately measure the allocated aperture. Fridge dimensions measure up to 2115mm height, 1440mm width and 768mm depth with a maximum gross capacity of 1227 litres as seen with the Inomak CEP2144SL Fridge. Freezer dimensions measure up to 2130mm height, 1480mm width and 850mm depth with a maximum capacity of 1410 litres as seen with the Tefcold RF1420 Upright Freezer. All of our storage fridge and storage freezer categories have height, width and depth filters to help you narrow down the equipment suitable for you.

![]() Top Tip: Allow for external airflow. All refrigeration needs space to breathe. Without it, components are likely to overheat causing a decrease in efficiency, loss of performance and ultimately breakdowns. At least a 5cm airgap should be allocated around the exterior of the equipment.

Top Tip: Allow for external airflow. All refrigeration needs space to breathe. Without it, components are likely to overheat causing a decrease in efficiency, loss of performance and ultimately breakdowns. At least a 5cm airgap should be allocated around the exterior of the equipment.

Some premises may benefit from slimline designs such as the Foster FSL800H Double Door Fridge. This can not only make the most of the space you have available but can also help when getting equipment into awkward buildings or fitting through narrow doorways.

![]() Top Tip: Storage fridges and freezers can be quite large so always consider actually getting the unit into the building and into position. Once an order has been placed, there will be a cost to return the equipment should you find upon delivery that you can't actually fit it into the building or round that tight corner into the kitchen. For more information take a look at our Delivery and Returns page.

Top Tip: Storage fridges and freezers can be quite large so always consider actually getting the unit into the building and into position. Once an order has been placed, there will be a cost to return the equipment should you find upon delivery that you can't actually fit it into the building or round that tight corner into the kitchen. For more information take a look at our Delivery and Returns page.

All equipment will state the available capacity in litres. When noting capacity specifications always bear in mind whether you are looking at the gross or net figures. The gross capacity is based on the theoretical amount the cabinet should hold in direct relation to the external dimensions however the net volume is the actual usable capacity that the unit offers, much more useful to base decisions on.

Pay attention to the number of shelves or gastronorms that each unit holds. This will determine the levels you have available for storage and will vary between models.

![]() Top Tip: Specifications may state the total number of shelves that a unit can hold. This doesn't mean that this number is the quantity supplied. A model capable of accepting 18 shelves for example, may only include 6 as standard, any additional shelves needing to be purchased at an additional cost.

Top Tip: Specifications may state the total number of shelves that a unit can hold. This doesn't mean that this number is the quantity supplied. A model capable of accepting 18 shelves for example, may only include 6 as standard, any additional shelves needing to be purchased at an additional cost.

When calculating the capacity you need, it may be tempting to go with the closest related unit. While it's undeniably pointless investing in equipment that's far too big for your storage

Foster Cold Room

Foster Cold Roomrequirements (you'll end up cooling wasted space) it is worth remembering that internal airflow is just as important as that flowing externally of the equipment. There needs to be ample airflow to allow the cold air to circulate and generate even and consistent storage temperatures. If you find you're having to stuff the cabinet to fit in all of your stock, you need to be investing in larger equipment. Overfilling can have a negative effect on performance and efficiency.

There's plenty of size and capacity options available, so whether you're a smaller business looking for compact under counter solutions or larger operations opting for single or double door fridges and freezers, there's a piece of equipment to suit. If chilled cabinets within this category just aren't large enough to meet storage demands, then the ultimate storage - a cold room or freezer room is worth considering. Check out our Cold Room Buying Guide for more details including advice and top tips.

Always bear in mind that the larger the capacity, the greater the cost to purchase and the higher the running costs due to the size.

Positioning and Placement

Any storage refrigeration needs to be easily accessible from the kitchen whether it is placed in a separate storage area next to the kitchen (where ambient temperatures are cooler) or actually within the working area (in higher ambient temperatures). The intended placement is a critical factor when determining the type of equipment you need.

While some 'storage' fridges and freezers are designed for placement away from the high heat of the working kitchen, other units classed as 'catering' can work effectively in high temperatures. To ascertain the suitability of equipment look-out for the Climate Class. This denotes the maximum ambient temperature in which a unit can effectively and efficiently perform.

Once the initial placement has been confirmed and potential equipment filtered down, you must consider other features such as the position of the motor. Fridges and freezers will have either under-mounted or top-mounted refrigeration systems. This is easily ascertained by noticing where the visible vents are situated - the top or the bottom.

Under-Mounted or Top-Mounted?

| Refrigeration Position | Benefits |

Undermounted; the motor positioned at the bottom of the cabinet |

Draws in low air which is cooler, reducing strain on refrigeration |

| Ideal for premises with low ceilings | |

| Easy access to components during servicing and maintenance | |

Top-Mounted; the motor positioned at the top of the cabinet Top-Mounted; the motor positioned at the top of the cabinet |

Draws in cleaner air, without the dust and debris that may be present at floor level |

| Hot air from the refrigeration cycle rises from the top of the unit creating a more comfortable working environment | |

| Heavier cold air produced falls down through the cabinet to assist with cooling |

Refrigerated drawers will not have top-mounted systems, instead offering the option of side vented, rear vented or bottom vented positions. The Tefcold Uni-Drawer range is manufactured with under-mounted or bottom vented refrigeration as standard however Adande drawers are available as side or rear vented models. This ensures that optimum airflow can be achieved in any kitchen layout.

Cooling and Defrost Functions Explained

Commercial solid door storage refrigeration uses a number of different cooling methods to achieve required temperatures and employs a variety of types of defrost to deal with any build-up of ice. How do you know which is right for you?

The right functions for your business will often depend on the results you expect to achieve and the time you have available to dedicate to maintenance. Here we explain each cooling and defrost function and the level of input required for each, to help you make the right decision for your business.

Cooling Systems

Static - Cold air is naturally circulated throughout the storage cabinet. While this can potentially save energy you may experience small pockets of warmer air and, in some cases, uneven chilling.

Fan Assisted - Fans circulate cold air evenly and consistently throughout the cabinet.

Defrost Functions

Manual - Time and labour intensive, manual defrost methods require you to empty contents from the equipment into a separate unit, switch off the fridge or freezer and remove ice any build-up by hand.

Automatic/Electric - Operates on a factory set cycle and requires no manual intervention. Heated elements thaw any ice build-up, the thawed water collecting in a condensate tray positioned near to the motor. The heat produced by the motor as it works causes the melted ice/water to evaporate.

Off Cycle - The refrigeration cycle is temporarily paused causing the unit to heat up sufficiently to melt any build-up of ice. The length of the pause will be defined by a factory set timer. At the end of the allotted period, the refrigeration cycle resumes bringing temperatures back down to chilling or freezing settings.

Will my Food Defrost During the Defrost Cycle?

It can be worrying (and potentially costly) when you have large quantities of valuable stock stored in your freezer and any rise in temperature could see it all thaw and be ruined, so having a few reservations about any defrost cycle occurring when you still have foods stored is understandable.

During defrost, the refrigeration cycle is effectively halted and heated elements kick in to thaw any ice build-up. This planned rise in temperature should only be by a few degrees and shouldn't compromise the integrity of your stock. The actual core temperatures of food shouldn't vary with such minimal fluctuation. Of course, the type of food you have stored will determine different reactions to any temperature rise, even if it is only by a few degrees. Water-based products, for example, will thaw more quickly than large solid cuts of meat.

If you find that foods are thawing during an automatic defrost cycle there are a number of possibilities. One could be that the defrost cycle may be set to occur over too long a time frame. As it is a factory set timer, the length of defrosting is averaged out between all possible factors including stock quantities and usage etc. and will not be tailored to your individual business. Another factor could be that there is some other underlying issue with the refrigeration system. Alternatively, it could simply be that, during the defrost cycle the door or lid is being opened or the seals are not performing as efficiently as they should, therefore, letting cold air escape.

If thawing persists, contact your supplier.

This worry is redundant when using manual defrost functions as all stock is removed and located elsewhere before the freezer is switched off.

Specifications and Features of Solid Door Refrigeration

True T49FZ Gastronorm Solid Door Freezer

True T49FZ Gastronorm Solid Door Freezer- The number of shelves in each unit will vary. The size of the refrigeration will dictate the number of shelves that are present, obviously the larger the equipment the more tiers are available. The majority of manufacturers will feature adjustable shelves allowing the user to fully personalise the interior design to complement their storage requirements. Some models will be suitable for the storage of gastronorms such as the Interlevin AF07BT Solid Door Freezer (GN pans). This allows greater quantities of products to be moved with ease to and from storage. Alternatively, drawer units are available to deliver greater storage versatility.

- Storage shelves or pan slides. Some businesses may only require their refrigeration to store sheets of prepared items. If this is the case for your business, pan slides in place of storage shelves will allow smoother and easier access.

- Choice of exterior finish. Most refrigerators will be sold with a standard aluminium exterior however stainless steel or vinyl options are becoming increasingly popular variants. These latter two materials are worth consideration as they are easier to clean and are often thought to be more durable. The choice of stainless steel, aluminium or white exteriors are generally available.

- Castors. Some models such as the Inomak CFP2144SL Solid Door Freezer will feature castors as standard, either positioned at the rear or as a full set, to increase mobility of equipment meaning that hygiene and cleaning around that area is made substantially easier. There will be no more lugging of heavy equipment or reaching behind units to ensure a thorough clean; simply rolling out the refrigeration will leave adequate space to clean and sanitise effectively. If you have exceptionally large and heavy pieces of equipment, castors will guarantee that no one gets injured whilst attempting to move the unit.

- Single or double door options are available with catering fridges and freezers. On single door models, there may be the choice of right or left hinged doors however this isn't a standard option. Depending on the existing layout of your kitchen or storage area you may find that choosing left or right hinged can eliminate potential obstructions when opening and accessing the unit.

- Self-closing doors can come in handy during busy services when staff under time restrictions may accidentally leave the door ajar in their haste. Letting the doors take care of themselves can increase efficiency and prevent the unnecessary escape of cold air.

- For premises looking for added security for valuable stock, locks can be a great addition. Securing contents whilst unattended, safety is guaranteed.

Getting to Grips with Refrigerants

All equipment designed to chill or freeze requires some form of refrigerant to enable the refrigeration cycle to work. Understanding these refrigerants and what the letters and numbers stand for can be a little confusing. Here we aim to break it down for you, so you know exactly what you're looking for when buying storage refrigeration.

R404a / R134a - these refrigerants are classed as HFC's or hydrofluorocarbons. Brought into the market to replace ozone-damaging CFC's, it has since been shown that while not having the same disastrous effect on the ozone layer, these gases do possess a high GWP, or Global Warming Potential. GWP relates to the quantity of heat that the gas traps in the Earth's atmosphere contributing to global warming. HFC's are systematically being phased out in favour of HC's.

R600a / R290 - these refrigerants are classed as HC's or hydrocarbons. Considered more environmentally friendly and efficient these gases have a low GWP. Unlike HFC's, which can be serviced by any refrigeration engineer, HC's are flammable and require a specialist trained refrigeration engineer to carry out servicing and maintenance.

With growing environmental awareness and the introduction of F-Gas Regulations, manufacturer's are beginning to make the switch from HFC's to more environmentally sound HC's. As HFC's are being phased out (and due to environmental factors) opt for HC refrigerant gases where possible.

Efficiency and MEPS

Typical solid door cabinet refrigeration isn't considered the most efficient in terms of design although it works well for its intended purpose of offering large capacities and easy accessibility to stock. These upright cabinets, when the door is opened, allows both warm and cold air to escape from the full length of the unit. The exception is with refrigerated drawers which create a cold well similar to that of a chest freezer.

A common feature in all commercial refrigeration is the high-grade insulation and heavy duty manufacturing materials that to help contain cold temperatures and achieve consistency in chilled storage conditions. Good quality seals also help to prevent the escape of cold air.

Never overfill the interior of the equipment causing obstruction to the internal airflow or fail to leave ample airflow around the exterior of the unit as this will impact efficiency.

What are MEPS?

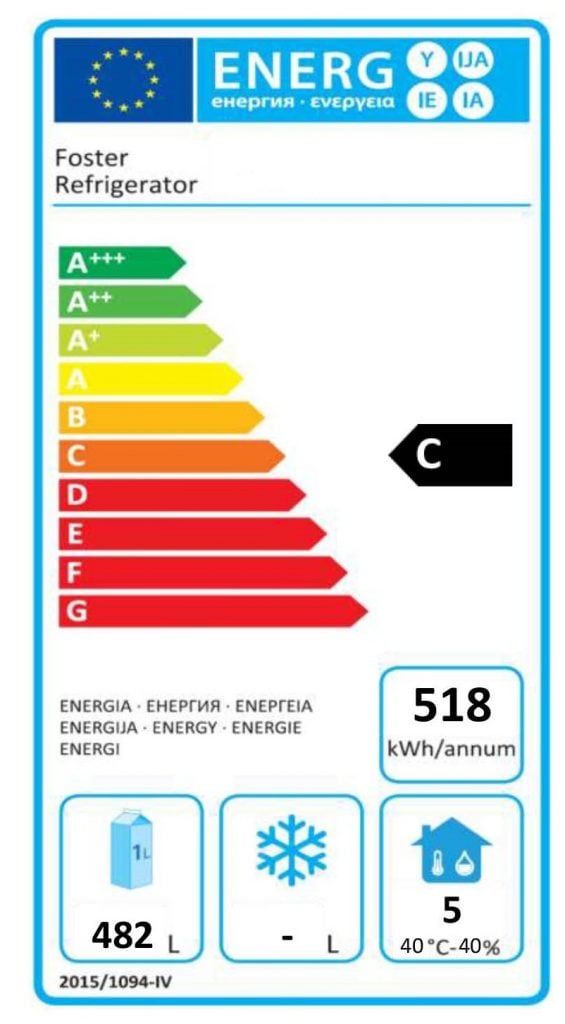

MEPS or Minimum Energy Performance Standards were introduced as part of the Ecodesign Directive on 1st July 2016. Basically, all fan assisted solid door refrigeration must be subjected to standardised testing and the results recorded. An energy label or grade is awarded and must be displayed on all product information pages. Rated on a scale of A+++ to G, these labels can be used as a guideline to ascertain the projected efficiency of the equipment when operated in the outlined conditions and ambient temperatures stated on the label.

![]() Top Tip: Never buy on MEPS ratings alone. While it should always be factored into your final purchasing decision, it is vital to make sure that the unit you choose is the right one for your intended purpose with regards to all aspects and specifications, not just because it has the best efficiency rating. There's no point buying an 'A+++' grade fridge, tested at a Climate Class 3 if you intend to position it and operate actually within a hot kitchen environment of Climate Class 4 or above. Just because a model is super efficient in cooler ambient temperatures it doesn't mean it will be more efficient in hot temperatures. The efficiency grade given is only in line with the stated maximum ambient temperatures and conditions in which it was tested.

Top Tip: Never buy on MEPS ratings alone. While it should always be factored into your final purchasing decision, it is vital to make sure that the unit you choose is the right one for your intended purpose with regards to all aspects and specifications, not just because it has the best efficiency rating. There's no point buying an 'A+++' grade fridge, tested at a Climate Class 3 if you intend to position it and operate actually within a hot kitchen environment of Climate Class 4 or above. Just because a model is super efficient in cooler ambient temperatures it doesn't mean it will be more efficient in hot temperatures. The efficiency grade given is only in line with the stated maximum ambient temperatures and conditions in which it was tested.

It's also worth taking into account whether equipment features on the ETL (Energy Technology List). Units that appear on this government list are eligible on the ECA Scheme (Enhanced Capital Allowance) and have proven to benefit from increased efficiency. Read more about this scheme on our ECA page.

Cleaning and Maintenance

Commercial solid door refrigeration is an important part of any catering and foodservice business, keeping foods fresh and preserving stock. Unfortunately, it's natural that equipment will develop faults at some point, whether that's due to age and mechanical failure or simply down to user error. Employing correct and regular cleaning and maintenance can reduce the risk of costly breakdowns and make sure you get the most out of your investment.

- Clean internal and external surfaces with warm, mildly soapy water and a soft cloth. Some level of food debris is a certainty in equipment designed to store food, regular cleaning can maintain hygiene and food safety.

- Make sure vents and refrigeration components are free of dust and debris. This can be done by wiping with a damp cloth or by using a nozzle attachment to vacuum the area.

- Check door seals for any signs of wear and tear. Well-fitted door gaskets create an effective seal to prevent the escape of cold air. When these seals are compromised, either through degradation or damage, they can't perform as they should, allowing air to escape and compromising performance and efficiency. Some brands fit their equipment with replaceable door gaskets ensuring that you get a strong secure seal throughout the lifetime of the equipment.

- Call in an expert. While there are plenty of ways to maintain your refrigeration in house, it is advised to get in a refrigeration expert at least once every year to give your equipment a full service and MOT.

- Keep a detailed log of all cleaning, service and maintenance procedures. Providing a checklist of all cleaning tasks for staff to complete on a daily, weekly or monthly basis is also a great way to monitor progress and make sure all cleaning jobs are up to date and completed.

![]() Top Tip: Pay attention to any minor fluctuations in terms of storage temperatures or efficiency. Any variation can be an early warning indicator or sign of potentially bigger problems in the future. Don't wait till your equipment breaks completely, by then it's too late.

Top Tip: Pay attention to any minor fluctuations in terms of storage temperatures or efficiency. Any variation can be an early warning indicator or sign of potentially bigger problems in the future. Don't wait till your equipment breaks completely, by then it's too late.

The majority of commercial refrigeration is now designed with ease of cleaning in mind including features such as moulded inner liners and rounded internal corners to prevent hard to reach areas that are potential traps for food debris.

Choosing your Warranty

When refrigeration goes down it can be inconvenient and very expensive, not only to fix the issue itself but also covering costs of any wasted stock. While your warranty won't offer compensation for foods lost through refrigeration breakdown it will help you to get your equipment sorted, whether in part or totally.

The warranty available will depend on the manufacturer and will usually range from a parts only cover to a full warranty that covers parts and labour costs. The duration of this cover will vary, usually over either a one or two year period. Before placing your order always check which elements you are covered for and the overall duration of the warranty.

We Recommend:

We always advise our customers to obtain the highest level of warranty available to give peace of mind that should any issues arise due to manufacturer fault, you will receive the help and support you require for no additional cost.

To read more take a look at our handy guide to commercial warranties.

When Will My Order Be Delivered?

Deliveries will depend on the manufacturer and type of equipment you have purchased. This may range from 2-3 or 3-5 working days for stocked items. Larger equipment may have a longer lead time of 6-8 weeks or may be made to order which can again push back your expected delivery date. For more information regarding deliveries take a look at our FAQ's page or alternatively contact our customer service team on 01455 234776 and select option 3.

Determining Accessibility for Paid Position and Unpack Services

When ordering your refrigeration equipment you will need to stipulate the level of accessibility to your premises and also whether there are any steps that must be scaled to deliver your purchase if you have requested a position and unpack service at an additional cost. The weight of even a single unit can be unexpectedly heavy so prior thought and planning as to the safest way to deliver and place the item should always be given.

Thought must also be given to the access route once inside the premises to the final position of your fridge or freezer. Measure any doorways, corridors or potentially tricky corners to make sure you have enough space to manoeuvre units into place whether as part of a paid for service or carry out positioning yourself.

Get Advice

If you are still unsure as to which storage fridge or freezer is best suited to your requirements you should always seek further advice. Do you have friends in the same field? Listen to what they have to say however bear in mind that their equipment will be tailored to their individual business needs and may not be suitable for yours. Alternatively, you could ask the advice of an impartial supplier. The FFD team are trained to listen to your requirements and provide valid suggestions that best suit your criteria, giving honest and unbiased feedback.

By understanding the basic elements of commercial storage refrigeration in relation to the unique needs and requirements of your business and with careful consideration of the products available on the market you will be sure to make the right decision the first time around.

Leave a Comment

Your email address will not be published. Required fields are marked *