Representing the pinnacle of food safety, blast chillers and freezers pull core food temperatures down quickly through the food danger zone between 8°C and 68°C in line with and compliant with FSA guidelines and HACCP legislation. Not only limiting bacterial growth but also allowing safe extended storage to reduce food waste and permit advance preparation prior to busy services, blast chillers and blast freezers are a fundamental part of any commercial catering and foodservice operation.

Find out everything you need to know about buying blast chillers and freezers and guarantee that you make the right decision for your business and your customers.

Table of Contents

What are Blast Chillers and Blast Freezers?

Do I Need a Blast Chiller and Freezer?

What Does a Blast Chiller Do?

How Does a Blast Chiller Work?

The Benefits of Blast Chilling

Chilling and Freezing Capacities

What Is Storage Mode/Holding Function?

Size and Placement

Blast Chilling Programs

Cooling and Defrost Methods

Gastronorm (GN) Compatibility and Shelves

Features and Options

Know your Power Supply

Understanding Refrigerants

Cleaning and Efficiency

Manufacturer and Price

Commercial Warranty Cover

Ask Advice

What are Blast Chillers and Blast Freezers?

All commercial kitchens are required by law to implement measures that facilitate strict food safety. Blast chillers and freezers may look like any other refrigerated cabinet on the outside, whether that’s countertop or freestanding, however, underneath has a powerful fan system working away to rapidly cool or freeze foods ready for safe storage.

Do I Need a Blast Chiller and/or Freezer?

If your business serves food, then the simple answer is Yes. Food safety is a key aspect of every commercial foodservice operation regardless of whether that’s on a small or large scale.

All businesses that produce and serve food to the public must operate in line with the Food Safety Act 1990 – failure to do so may result in large fines or up to two years imprisonment. Businesses must show due diligence and prove that all reasonable precautions have been taken and guidelines adhered to, this includes but is not limited to, the correct chilling of foods within the stated time and accurate record-keeping.

What Does a Blast Chiller Do?

Expertly designed and offering a scientific approach to food safety, blast chillers and freezers must be able to pull temperatures down from:

- a maximum of 70°C to 3°C within 90 minutes in the case of blast chillers (also known as shock chillers)

and from

- a maximum of 70°C to -18°C within 240 minutes in the case of blast freezers (aka shock freezers).

All equipment on the market must be able to, in the least, meet these criteria, however, with advancements in design and technology, some units now far exceed these time frames, even from higher starting temperatures of 90°C.

The blast chilling process quickly pulls down temperatures, denying bacteria the opportunity to multiply, thus enhancing food safety.

![]() Top Tip: Large joints of meats, as more dense, will not chill within the required time when whole. It is recommended to portion joints before chilling or freezing.

Top Tip: Large joints of meats, as more dense, will not chill within the required time when whole. It is recommended to portion joints before chilling or freezing.

How Does a Blast Chiller Work?

Using powerful fans, cold air is evenly and consistently circulated throughout the cavity and passed over the surface of the foods. This continuous movement means that cold temperatures are easier to achieve and maintain. The result is a rapid chill or freeze.

A blast chiller forces super cold air over and around the surface of foods to quickly pull down temperatures. Blast freezing is sometimes referred to as IQF (Individually Quick Frozen) or quick frozen food. Rapid freezing leads to smaller ice crystals being formed within the food. These small crystals preserve the quality of foods and have less impact on texture, taste, nutritional value and form when items are removed from storage, and correctly defrosted and regenerated.

The alternative to IQF is cold store freezing where large bulk quantities of product are frozen as a whole unit. This method takes a lot longer to achieve the desired temperatures and effect. The longer freezing process results in the formation of larger ice crystals which can have a negative effect on product quality. For businesses that need to blast freeze large quantities of product, cold rooms and freezer rooms with a blast chill or blast freeze function are available, although will be costly to purchase and operate.

Tefcold BLC10 Blast Chiller and Freezer

Tefcold BLC10 Blast Chiller and Freezer

Blast chilling and freezing also rely on the amount of space between the inserted trays of food. By increasing the gap between trays, airflow is maximised, meaning that cold temperatures more easily envelop the contents, reducing chilling times. Read more here about the Story Behind Blast Chilling.

![]() Top Tip: Never substitute a blast chiller for a standard fridge or freezer whether domestic or commercial. Standard refrigeration will not adequately chill hot foods within the stated time frame. Putting hot foods in a standard domestic or commercial refrigeration unit will only succeed in raising the internal temperature of the equipment. This means that components must work harder to perform, achieve and maintain appropriate temperatures. This exerts extra strain on refrigeration systems leading to reduced lifespan and ultimately compromising the safety and integrity of all food contents.

Top Tip: Never substitute a blast chiller for a standard fridge or freezer whether domestic or commercial. Standard refrigeration will not adequately chill hot foods within the stated time frame. Putting hot foods in a standard domestic or commercial refrigeration unit will only succeed in raising the internal temperature of the equipment. This means that components must work harder to perform, achieve and maintain appropriate temperatures. This exerts extra strain on refrigeration systems leading to reduced lifespan and ultimately compromising the safety and integrity of all food contents.

The Benefits of Blast Chilling

![]() Heightened food safety in accordance with FSA and HACCP legislation and guidelines

Heightened food safety in accordance with FSA and HACCP legislation and guidelines

![]() No compromise to flavour, texture or nutritional content

No compromise to flavour, texture or nutritional content

![]() Minimises dehydration and weight loss of foods during storage

Minimises dehydration and weight loss of foods during storage

![]() Safe storage for pre-prepared foods

Safe storage for pre-prepared foods

![]() Allows for preparation in advance of busy services or large catering events

Allows for preparation in advance of busy services or large catering events

![]() Added protection for customers, minimising the risk of potential cases of food poisoning

Added protection for customers, minimising the risk of potential cases of food poisoning

![]() Reduces waste by safely storing foods that would otherwise spoil

Reduces waste by safely storing foods that would otherwise spoil

![]() Saves time and money

Saves time and money

Chilling and Freezing Capacities

The main question you need to be asking is ‘how much food do you need to chill or freeze in one cycle?’

Ultimately, the capacity you require will depend on the scale of the operation you run, the size of the kitchen and the quantity of food you produce or need to pre-prepare. The larger the business, obviously the greater the required chilling and freezing capacity.

Addressing the maximum capacities of each model is one of the most vital aspects to get right when choosing shock chillers. All equipment will show the chill capacity: those with freeze functionality will state this information separately.

Freeze and chill functions will each have differing limits – maximum quantities for effective freezing being less than those for chilling. Although some models may show capacity in the form of litres, it is typically displayed in kilograms.

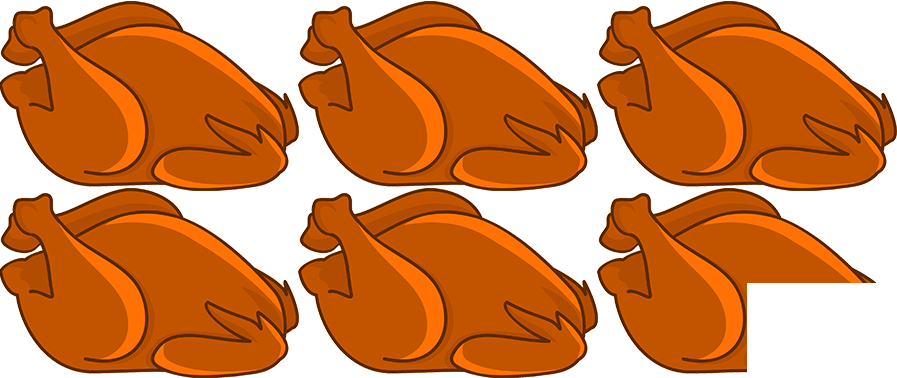

| Chill capacities range from: | ||||

|

10kg |

(approx. 5 ¾ medium chickens) (approx. 5 ¾ medium chickens) |

to |

52kg |

(approx. 29 ¾ medium chickens) (approx. 29 ¾ medium chickens) |

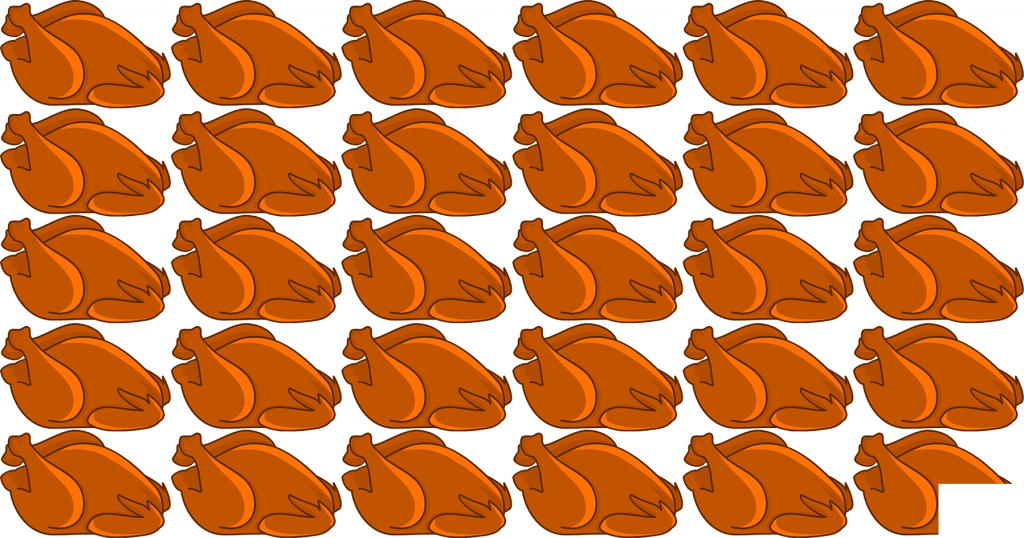

| Freeze capacities range from: | ||||

|

8kg |

(approx. 4 ½ medium chickens) (approx. 4 ½ medium chickens) |

to |

26kg |

(approx. 14 ¾ medium chickens) |

![]() Top Tip: Always choose a capacity the same or greater than your needs. Buying something with less capacity and hoping to just squeeze a bit more in will not work. Overfilling of the cabinet will reduce the effectiveness and performance of the chilling or freezing process, potentially jeopardising food safety.

Top Tip: Always choose a capacity the same or greater than your needs. Buying something with less capacity and hoping to just squeeze a bit more in will not work. Overfilling of the cabinet will reduce the effectiveness and performance of the chilling or freezing process, potentially jeopardising food safety.

What Is Storage Mode/Holding Function?

Some models will feature a storage mode also referred to as a holding function. This means that once the blast cycle has ended, the cabinet will automatically switch to a holding function where contents are suspended at appropriate temperatures and in optimum condition until removed and placed in alternative refrigerated storage. Storage mode will accept higher capacities than during blast cycles.

Why?

Blast chill/freeze cycles rely on ample space between each GN level in order to allow air to circulate effectively and rapidly pull-down temperatures. Storage doesn’t require this additional space as the core temperatures of foods are already at recommended levels, hence more product can be fitted in.

Size and Placement

The intended placement of your equipment will dictate the size you’re looking for. With countertop, under-counter and freestanding models available, each increasing in size, there’s a unit to accommodate all requirements.

Choosing the Right Sized Chiller

- Measure: Accurately measure the space you have available and use this as your guide.

- Measure again: Before completing any purchase, we always advise re-checking your initial measurements. If you have made an error in your equipment choice and the order is processed and dispatched, there will be a restocking fee if you suddenly realise it’s not suitable. For more information about returns and cancellations take a look at our Delivery and Returns Quick Facts.

- Check access points: Will the equipment actually fit into the premises? Measure all access points en route to the final destination of the unit. This includes exterior doorways, internal doorways and corridors or walkways, paying particular attention to any tight corners that might be encountered on the way.

What about Placement

Let’s start with the obvious: is it for placement on a countertop, under an existing work surface or as a freestanding unit? Although typically formatted in a cabinet style with hinged door access, freestanding drawer layouts are available for added versatility.

Adande refrigerated drawers with blast chiller offer the flexibility of fridge or freezer storage with the added convenience of an in-built blast chilling function. Whether you’re looking for undercounter, non-load bearing drawer units or with a ‘hot cookline’ top that can be used to support countertop cooking equipment, Adande can supply exactly what you need.

![]() Top Tip: If you’re working in a galley style kitchen always allow ample space to access the unit. Remember that the overall depth of the chiller will be greater when the door or drawer is opened.

Top Tip: If you’re working in a galley style kitchen always allow ample space to access the unit. Remember that the overall depth of the chiller will be greater when the door or drawer is opened.

The placement of the blast chiller in relation to the layout of the kitchen will also need some consideration. Equipment will generally need to be within the near vicinity of the kitchen prep area in order to optimise efficiency when transferring foods to and from the unit. It is vital, however, to always pay attention to the climate class awarded to the unit. This will give an indication regarding the maximum ambient temperatures and conditions in which the chiller can operate efficiently.

Refrigeration Positioning

We’ve spoken about the ultimate placement of the equipment but what about the basic design of the chiller itself? Refrigeration systems within the unit will typically be undermounted, top-mounted or side-mounted. This is easily determined by noting where the vents are visible.

Ensure good airflow to the refrigeration components, wherever they are situated, to allow ample breathing space. This helps equipment to perform effectively and efficiently. Refrigeration works hard, so make sure it gets sufficient air. We recommend at least a 50mm air gap around the exterior although up to 150mm may be required above the unit.

Blast Chilling Programs

Blast chillers will generally have at least two cycles – soft chill and hard chill.

Soft Chill is designed for delicate foods with a higher water content. This cycle prevents dehydration and preserves the integrity of the foods.

Hard Chill is considered the standard chilling cycle and is suitable for the majority of foods.

A Pre-Chill mode may be available that ensures the cabinet is at the optimum temperature prior to chilling. This improves overall performance, efficiency and the quality of the results.

Some equipment may also feature a Hard-Chill Max program designed to effectively bring down the temperature of foods with a higher fat content.

If you are looking for a blast freezer, equipment will also have a Shock Freeze program. This pulls down core temperatures to below freezing within the recommended time frame.

Chilling and freezing cycles will be determined by either a timer or temperature probe.

![]() Top Tip: Never remove food using the probe. This is a delicate instrument.

Top Tip: Never remove food using the probe. This is a delicate instrument.

While certain units will offer either one or the other, some models, such as the Foster BCT52-26 can operate with both methods, giving the user a choice of operation.

![]() Top Tip: Where a temperature probe is used to monitor core temperatures, the probe will require calibration typically once a month, although always check manufacturer recommendations. File away all calibration certification safely, so that full documentation can be provided if or when required. More details about checking and looking after your probe can be found in this Food Safety Practices document.

Top Tip: Where a temperature probe is used to monitor core temperatures, the probe will require calibration typically once a month, although always check manufacturer recommendations. File away all calibration certification safely, so that full documentation can be provided if or when required. More details about checking and looking after your probe can be found in this Food Safety Practices document.

It is recommended that cooked foods, especially meat, be allowed to rest and cool for approximately 30 minutes before being blast chilled or frozen.

Cooling and Defrost Methods

All shock chillers and freezers use fan assisted cooling methods to evenly and consistently circulate cold air for rapid chilling and freezing. Whilst all equipment works in line with regulations, some brands will utilise more powerful fans capable of producing quicker results even from higher starting temperatures.

Foster, for example, implement a Circulair ™ air circulation system into their standard range of equipment. This sucks the air rather than blows it to draw air over the surface of the food rather than hitting it with a direct stream.

Due to the dramatically dropping temperatures associated with blast chilling, a suitable defrost system is vital. Models will typically state either an automatic or off-cycle defrost system (although manual programs may be available which can be initiated at a convenient time). Both offer a hands-off approach to getting rid of any ice build-up with no human interaction necessary. The equipment will run a predetermined, factory set cycle periodically to eliminate any unwanted ice. Click here to read more about the different types of defrost.

Gastronorm (GN) Compatibility and Shelves

Interlevin AT05 ISO Blast Chiller and Freezer

Interlevin AT05 ISO Blast Chiller and Freezer

The very nature of a blast chiller is to chill or freeze a given quantity of products. In order to facilitate quick and easy movement of multiple products in one movement, units will often be gastronorm (GN) compatible. This means that users simply transfer a tray rather than individual items.

![]() Top Tip: Always check the GN size that each model is compatible with, whether that’s 1/1, 2/1 or other sizes as well as the number of trays that can be held. Make sure that this correlates with your requirements. It is recommended to use a tray no deeper than 25mm.

Top Tip: Always check the GN size that each model is compatible with, whether that’s 1/1, 2/1 or other sizes as well as the number of trays that can be held. Make sure that this correlates with your requirements. It is recommended to use a tray no deeper than 25mm.

While the majority of models support manual loading and unloading of GN trays, there are roll-in versions available, compatible with Rational GN trolleys, to make moving high volumes of trays even easier.

The number of shelves that each unit holds is also variable, the amount generally increasing with the size of the cabinet. Chilling and freezing models will typically offer between three and fifteen shelving levels as standard, however, roll-in models will be more.

Please Note: Gastronorm trays are sold separately and while some shelves may be supplied, it is not standard with every chiller. Always check what the chiller or freezer includes.

![]() Top Tip: Don't cover or place lids on trays during the chilling and freezing process. This will increase the amount of time required to chill the foods to recommended temperatures.

Top Tip: Don't cover or place lids on trays during the chilling and freezing process. This will increase the amount of time required to chill the foods to recommended temperatures.

Features and Options

Although all blast chillers fundamentally perform the same job, you will find that premium equipment may include a few extra touches. Look out for touch control panels, digital memory settings, and intuitive shut-off at the end of a cycle. These elements ensure that the unit remains intuitive, easy to use and convenient.

A holding or storage mode is also a great asset in any fast-paced kitchen. Read more about holding functions and storage modes here.

Another useful feature is found with certain Foster cabinets. Offering Automatic Surface Protection, frost burn or wind chill damage to the food is prevented by automatically adjusting and controlling the speed of the airflow.

Keeping detailed records is vital in blast chilling and blast freezing processes. If manually filling out sheets just isn’t a viable option for your business you will find that some top of the range equipment may be able to record temperatures for you.

Not all features and options need to be technology-based. You may also want to address whether the chiller has legs or castors as standard. While this won’t affect the operation and performance of the unit, it will make a difference when manoeuvring equipment. Generally larger equipment will be fitted with castors as standard to ensure that initial placement and subsequent cleaning of the surrounding area is simple. If castors don’t suit your requirements, there may be leg options available. The largest blast chillers may even have both as standard for extra stability combined with easy movement when necessary.

Replaceable door gaskets are always a beneficial feature. This not only helps with cleaning and hygiene maintenance but also to ensure that a good seal is always maintained for efficiency purposes.

Many models will give signals and notifications, whether visually or audibly. This may include end of cycle notification, high or low temperature alarms, or signal of a temperature probe fault. This means you are always aware of an action or problem straight away.

![]() Top Tip: Keeping comprehensive, detailed records and documentation is key. Should any allegations of improper food safety arise, EHO’s will want to inspect the site, observe chilling and cooling methods and investigate all records including temperature logs and operational procedures. These records should be kept for at least 3 months although longer is preferable. Read more about food safety hazards and record-keeping in this Critical Control Point Records document.

Top Tip: Keeping comprehensive, detailed records and documentation is key. Should any allegations of improper food safety arise, EHO’s will want to inspect the site, observe chilling and cooling methods and investigate all records including temperature logs and operational procedures. These records should be kept for at least 3 months although longer is preferable. Read more about food safety hazards and record-keeping in this Critical Control Point Records document.

Know your Power Supply

Before placing an order always check the required power supply against that which your building is set up to accept. If you order a large 3 phase unit and your premises isn’t wired up for such, you may find that converting can be costly.

As a general rule, the larger the equipment and greater the capacity, the higher the power supply required to perform.

Standard 3 pin plug 13A

Standard 3 pin plug 13A

You will typically find equipment runs on one of three power supplies. Small, compact blast chillers will often use a single phase connection up to 13Amps. These units will be fitted with a standard 3 pin plug that can be plugged directly into a wall socket. Installation can be carried out yourself without the need for a qualified electrician.

As size and capacity increase, so does the power supply. Mid-size equipment will typically run with a single phase connection with greater than 13A. This is a hardwired connection that is wired straight into a fused spur and will require installation by a qualified electrician.

3 phase electrical connection

3 phase electrical connection

Larger units that have greater power requirements will require a 3 phase set-up. This gives more consistent flow to the machine, each phase reaching its peak sequentially to prevent any drop-out of power. 3 phase supplies use a special connection and will require installation by a qualified electrician.

Understanding Refrigerants

Refrigerant is the ingredient that actually chills the equipment. There are many different refrigerant gases available and you should always make yourself aware of the basics before you buy a blast chiller.

Commercial refrigeration currently uses either HFC’s (hydrofluorocarbons) or HC’s (hydrocarbons). While both types of gas are accepted at present, F-Gas Regulations state that by 2020, all newly manufactured equipment must use HC’s only. Older models using HFC’s will still be able to be serviced and used but will not be available as new from the production line.

This is a worthwhile fact to bear in mind when initially choosing your refrigeration. Do you want to buy a new unit that will soon be outdated gas-wise or invest in the most environmentally sound option from the get-go?

What Are the Differences Between HFC’s and HC’s?

HFC’s include gases R404a, R134a and R452a. These gases have a higher global warming potential (GWP). This measure is used to determine how much heat the gas traps in the Earth’s atmosphere.

HC’s include gases R290 and R600a. These gases have a low GWP and are approved under the F-Gas Regulations. You must use a certified F-Gas engineer to carry out servicing and maintenance on these gases due to their flammable properties.

While some brands currently offer HFC gas, they are in the process of phasing this out, bringing in HC replacements. Certain brands may offer the option, while others have already made the switch. Be sure to check the type of gas used in your intended piece of equipment so you know what you’re dealing with.

Cleaning and Efficiency

Cleaning is a vital factor in looking after your equipment and ensuring maximum food safety and hygiene. Following appropriate cleaning guidelines will also make sure that you get the best performance from your chiller and that you benefit from efficiency of operation and longevity of the unit.

Equipment is often designed with rounded internal corners to eliminate inaccessible areas where food debris could potentially collect and become a breeding ground for bacteria.

Basic Cleaning and Maintenance Checklist

- Clean all interior and exterior surfaces with mildly soapy water and a damp cloth. This includes shelves, tray slides and temperature probes.

- Regularly check the accuracy of the probe: an inaccurate probe could potentially result in unsafe chilling and freezing.

- Check the door seals to remove any food debris that may be present and also to check for any signs of damage or wear and tear.

- Keep vents and refrigeration components clean and clear of dust or debris.

- Keep up with regular servicing and maintenance by a qualified engineer.

Efficiency and Climate Class

Shock freezers and chillers are often positioned close to the heart of the kitchen where pre-prepared foods can be quickly transferred ready for safe cooling. Ambient temperatures in these areas will typically be higher due to the presence of cooking equipment and the heat that is kicked out from this.

The role of refrigeration to cool is counter-intuitive to these high temperatures and can, therefore, affect the efficiency of the unit, the ability to perform as expected and also the lifespan of components that have to work harder to achieve and maintain the cold conditions. Manufacturers test commercial refrigeration and award each a Climate Class. This represents the maximum ambient conditions that the unit can work efficiently and at optimum levels.

Blast chilling units will generally be constructed and tested to withstand Sub-Tropical (ST) or Climate Class 4 conditions. Both of these grades can withstand the effects of hot, humid environments without compromising performance or efficiency.

Manufacturer and Price

Blast chillers and blast freezers are advanced pieces of kit and are vital to food safety in any foodservice business. As such equipment can be pricey. We aim to give solutions to suit all budgets with units from a range of manufacturers.

The basic functionality doesn’t vary between brands and models however the level and range of programs and features does. Rest assured that whether you’re looking at the bottom or top of the budget scale, you are guaranteed reliable and consistent food safety.

Although the majority of manufacturers offer only a standard range at varying price points, premium refrigeration brand Foster also provide a range alongside their regular choices for businesses working to a strict budget. This UK brand are renowned for their high quality construction and advanced technology and efficiency and have designed their Xtra range with these core values in mind. Now, everyone can benefit from Foster guaranteed quality but minus any additional features that aren’t detrimental to operation: the features that will typically push up the price.

![]() Top Tip: Leading refrigeration brand Adande also offer refrigerated drawers complete with a blast chill functionality for ultimate versatility from your commercial refrigeration.

Top Tip: Leading refrigeration brand Adande also offer refrigerated drawers complete with a blast chill functionality for ultimate versatility from your commercial refrigeration.

Struggling with Cash Flow? Why Not Lease?

Leasing options are available on all orders totalling £1000 or over, exc. VAT. This allows businesses to make the most of their purchases and put them to good use without the large upfront cost. Not only does this free up cash flow and mean that every business can benefit from the best but also allows you to spread the cost into manageable monthly repayments.

If leasing isn’t for you, Foster also offers a 0% interest-free credit option. For more details on leasing and Foster credit take a look at our Commercial Leasing page.

Commercial Warranty Cover

The level and term of a commercial warranty with vary between manufacturer. Generally, you will find either 2 year parts only cover or 2 year parts and labour warranty as standard. Where ‘parts only’ is offered as standard there will often be the option to upgrade and purchase additional labour warranty to complete your level of cover.

We Recommend:

Always secure the most comprehensive level of warranty cover you can. Paying that little bit extra for a full warranty can save you money on costly engineers call-outs in the future should you experience any problems.

Ask Advice

When it comes to food safety and your business it’s vital to make the right decisions. We always recommend asking advice, whether that’s from a colleague operating in the same area or from a knowledgeable, impartial 3rd party. Always remember that someone else’s advice will be specific to their operation and may not be suitable for your business.

At FFD our team is fully trained to listen to specific needs and requirements and tailor equipment suggestions accordingly to make every shopping experience as smooth and stress-free as possible whilst guaranteeing that you get the right unit for the job.

Leave a Comment

Your email address will not be published. Required fields are marked *