Commercial bottle coolers are an essential for any pub and bar from local boozers to high end cocktail joints. Designed to keep bottled drinks at the perfect temperature whilst optimising display with glass doors, or boosting efficiency with solid doors; a comprehensive range of back bar fridges are available to meet every demand and suit all budgets.

Having collaborated with our team of in-house refrigeration engineers and experienced sales team, we have compiled this guide which aims to offer assistance throughout the whole buying process.

From choosing the unit that meets your requirements and uncovering which features may be important to you, to top tips for energy efficiency and increased equipment life span, we are with you every step of the way.

Table of Contents

What Is a Bottle Cooler?

Why Buy Commercial Bar Refrigeration?

Intended Placement of your Drinks Fridge

Measuring your Bottle Fridge

Getting the Right Capacity

Choosing a Door Type

Bar Cooler Temperature Ranges

What Specifications Should I Look For?

Refrigerated Modular Bar Systems

Bar Display Fridge Efficiency Explained

Understanding Refrigerants

Choose your Finish

Brand, Manufacturing Quality and Price

Get to Grips with Bar Fridge Warranty

Cleaning, Servicing and Maintenance

Ask Advice

What Is a Bottle Cooler?

The perfect way to store bottles at optimum serving temperature whilst also creating an appealing and enticing display, bottle coolers are stalwarts in any hospitality setting including pubs, bars, restaurants, cafes or bistros. Typically with a glass door design, solid door models are also available when display isn't required.

Why Buy Commercial Bar Refrigeration?

Designed and manufactured for use in hospitality settings, commercial bar refrigeration is tailored specifically to meet the tough conditions encountered in a business environment. Refrigeration systems are more heavy duty than domestic counterparts with the aim that consistent temperatures can be maintained even when subjected to the continuous open and closing of doors typical during working hours. These larger cooling systems will inevitably produce more noise, although this shouldn't be too noticeable in the hustle and bustle of a working bar.

Commercial equipment will generally be constructed using high grade materials to deliver the strength and durability required to withstand any knocks, bumps and scrapes common in day to day operations.

Intended Placement of your Drinks Fridge

The requirements of every business will greatly differ and so there are various options on the market to ensure that every demand is met and all bar spaces maximised. It is vital to create a bar layout that is not only efficient to work in but also attractive to the customer. This is simple thanks to the plethora of choice available. Choose from compact under counter models with a single door, double doors or triple doors constructed to sit beneath existing bar counters or tall upright designs with single door or double doors that deliver greater capacity.

Designed primarily for positioning front of house in average ambient temperatures, bar fridges attractively display your range of drinks to customers. Commercial drinks fridges are not manufactured for use in commercial kitchens where average ambient temperatures are a lot higher. Performance and efficiency will be affected, strain on the compressor is increased and ultimately the lifespan of the unit is dramatically reduced.

Where storage is a prime concern, chest coolers or bottle dumps can be a great solution. With a high capacity to hold large quantities of product, there's always plenty of perfectly chilled bottles on hand and ready for service. The top loading design offers a great way to improve efficiency and makes it easier for coolers to maintain low temperatures. Consider where cold air sits in a fridge…at the bottom with the hot air rising. When you open a forward facing door as with standard bottle fridges, this cold air is given the perfect quick escape route. In a top loaded unit, when the lid is opened, the cold air remains in the bottom of the cavity.

Looking to equip a hotel room? Hotel mini bar fridges are essentially a compact bottle cooler designed to hold drinks, milk and other essentials in correct temperatures. Where these mini bar fridges differ from standard drinks fridges is that they use static cooling systems and offer 'silent' operation with low decibels to minimise noise disruption, making sure that guests can enjoy perfectly chilled drinks and a good nights sleep.

Can I Use a Commercial Bottle Cooler at Home?

Commercial equipment is designed for commercial use. While units can be placed in domestic settings, there are a few issues that could cause problems. Noise levels when the chiller is in use are a lot higher than your average domestic fridge freezer. While not noticeable in the hustle and bustle of a busy pub or bar, it can be an issue in relatively quiet home environments.

Warranties can also be a sticking point. The majority of manufacturer’s warranties only cover use in commercial premises; when not used in this capacity, the warranty is null and void. Currently, only warranties from Blizzard and Osborne may be honoured when used in domestic settings.

We do not recommend that commercial bottle fridges be used for domestic purposes.

Measuring your Bottle Fridge

It is essential to accurately measure maximum external dimensions to guarantee that the unit you choose will fit into the intended location.

- It’s vital to allow for ample air circulation around the bottle fridge, typically 5cm around the entire exterior including above the unit.

Equipment needs to breathe in order to perform to appropriate standards and any obstruction could potentially cause technical issues in the future.

Once you’ve determined that the equipment you have your eye on will fit, it’s always best to measure any access points as well. Narrow doorways can severely hinder getting your bottle chiller into position and refusal to accept delivery at this stage will result in a restocking charge, possibly up to 50%.

Getting the Right Capacity

The total capacity of a unit is a vital consideration as this determines the quantity of stock that can be housed. Larger pubs and clubs that experience high turnover will obviously need a larger capacity to guarantee that chilled bottles are always available. Whilst this figure is often displayed in litres, it’s always handy to look for a bottle capacity, if available. Typically stating the number of standard 330ml bottles that can be stored, it will give you a better idea of the level of stock that can be displayed at one time.

The overall bottle capacity will obviously vary depending on the size of the bottles stocked; larger bottles will take up more space and reduce the total number that can be stored.

Most bar display fridges offer adjustable shelves to allow for greater stock versatility. This means that interior layouts can be optimised and tailored to the size of the bottles. Double and triple door chillers often have split shelving, meaning that each section can have a different set-up, greatly increasing the range of beverages you’re able to offer.

Top Tip for Stocking your Bar Refrigerator

Top Tip for Stocking your Bar Refrigerator

Always adhere to capacity information and never overstock a bottle fridge; just as the exterior needs breathing space so does the interior. For effective cooling, chilled air must be able to circulate around the cabinet and over-filling will restrict the air flow. The majority of manufacturer’s assume that when the fridge is restocked it will be with bottles from a cellar or some other cold storage area and not with room temperature products. This means that the cooler gets a head start in the refrigeration stakes and perfectly chilled stock is achieved more quickly and with less strain on components.

Choosing a Door Type

Directly related to capacity is the number of doors that you’re looking for. Single, double and triple door designs are available, obviously each with increasing external dimensions and a greater potential capacity. With sliding or hinged door options, there is something to meet every preference. The space you have available may be a deciding factor when determining what the best door option for your bar is.

Which is Best, Sliding or Hinged Doors?

- Hinged doors will often have a self-closing feature, a great addition for both convenience and energy efficiency, especially in busy bars. As the temperature rises every time the doors are opened, self-closing doors will minimise the amount of cold air escaping. Always take into consideration that hinged doors will require more space than sliding alternatives and could create possible obstructions when open. Some single door units offer the option of left or right hinged doors, allowing you to tailor the format to suit individual layouts.

- Sliding doors are better suited to bars where space is limited, as they don’t protrude into working areas. There are some drawbacks however. Any sticky spillages or debris could cause potential jamming of the runners if not cleaned appropriately and it’s more difficult to notice, at a glance, when sliding doors are left open.

Should I Choose Glass or Solid Doors?

The majority of bottle coolers will have glass doors, designed to effectively hold low temperatures and display bottled drinks to customers in front of house locations. Whilst perfect for display purposes, glass doors will lose heat faster than solid alternatives; think of where your house loses most of its heat…through the windows. This door type is the most common choice for bars in this country.

Solid door bottle coolers are ideal when bottles need to be chilled but don’t need to be displayed. They hold low temperatures better and offer greater insulation and efficiency. Typically seen in warmer countries, solid door models have a standard opening design, as seen with glass door types.

Ultimately the door type you choose will depend on where you intend to position the unit, the average ambient temperature and whether you’re looking for display or storage.

Bar Cooler Temperature Ranges

Bar coolers are designed to hold a variety of stock including alcopops, beer, juices, tonics and soft drinks etc. each with its own ideal serving temperature. Equipment must be able to create storage conditions to complement every beverage.

While temperature ranges vary from manufacturer to manufacturer, try to choose a unit that covers approximately 4°C-5°C. This offers a good balance between the general recommended temperature at which most items can be stored effectively (4°C) and energy efficient running (5°C).

What Specifications Should I Look For?

Pay attention to any additional features and specifications available on each piece of equipment. Budget bottle coolers will often only offer the basics while more advanced models will come with greater benefits.

- Internal forced air circulation is highly recommended as the fan evenly and consistently distributes chilled air around the cabinet, effectively and efficiently cocooning stock at the ideal temperatures more quickly.

- Digital control and display is also a worthwhile feature, allowing greater precision and accuracy with settings. These elements also ensure that monitoring of temperatures is simple thanks to the ‘at-a-glance’ readout. Consider keeping a record of temperatures at certain points throughout the day; any large variation could give early signals of a potential problem.

- Internal lighting is another essential addition, allowing you to showcase your products in the most attractive way. LED lighting is always a preferable option as they are seen as the most efficient. Some manufacturer's will offer the option of different coloured LED lighting, allowing you to personalise your bottle display to suit your individual style.

- An integrated locking mechanism is also a noteworthy feature. This simple addition to the design, increases the security of valuable stock when bar fridges are unattended.

- Opt for wire or metal shelves and try to avoid plastic materials. Metal and wire options offer extra durability and extra strength when supporting multiple bottles.

- Replaceable parts, such as door seals can also be a great advantage. Rather than suffer a decrease in efficiency through damaged seals, you can easily rectify the situation and restore your bottle chiller to its former glory.

Pay attention to the wattage of the unit; the higher the wattage, the more energy is used. This isn’t necessarily a bad thing. Always take into account any beneficial specifications or features that could warrant the higher wattage.

We Recommend:

With regards to servicing and maintenance, Gamko offer a very useful feature. They implement a different coil to other manufacturers, designed to reduce the intake and build-up of dust on vents, compressors and condensers during daily operation. Although cleaning is still necessary, it can prove very beneficial in extending the lifespan of refrigeration systems.

For our best pick that offers a great balance between essential specifications and features, with outstanding level of warranty at a lower price point, check out the Arctica HEC816 Double Door Under Counter Bottle Cooler.

Refrigerated Modular Bar Systems

While the market is fully stocked with standard 'off the shelf' drinks fridges, designed to slot in with existing bar equipment, this isn't always a perfect fit especially when businesses have specific ideas and demands. During set-up of new enterprises or the refitting of bars, pubs and clubs, the need will often arise for a tailored layout, individual to each premises. This may be to make the best use of space or to create a truly unique setting that reflects the professionalism of the business.

Refrigerated modular bar systems deliver the benefits of a customised approach - an excellent way to personalise bar design and create an area that works for your business. Gamko offer a bespoke service working on a project basis including in-depth analysis of your bar layout, professional advice based on experience regarding the equipment best suited to optimise the available space, installation and full aftercare. The result - a distinctive bar that not only looks great but encourages functionality and efficiency.

For more information get in touch with the FFD team.

Bar Display Fridge Efficiency Explained

Energy efficiency is a key factor to consider when selecting a glass door bar display fridge, both to keep running costs low and observe environmental awareness. As a general rule, the better the brand, the better the quality of components and overall manufacture, therefore, the higher the efficiency. There are a few elements that you should pay attention to with regards to efficiency.

Consider the ambient temperatures that the cooler will have to work in. The refrigeration system will have to work harder in higher ambient temperatures to achieve the desired setting, leading to a decrease in efficiency. Always pay attention to the minimum and maximum recommended ambient temperatures as this will vary from manufacturer to manufacturer.

While the majority of manufacturers now offer LED lighting as standard, it is always worthwhile to check as this is a more efficient lighting method.

Look for double or triple glazed glass doors and good insulation; both help to keep the cold in and the warm out. Insulation helps to maintain temperatures even without the active refrigeration process, reducing the amount of work the compressor and condenser have to do.

Top Tips for efficiency:

1. Turn lights off at night.

2. Make sure doors are always securely closed.

3. Regularly check that seals are in good condition.

4. Don’t turn bottle fridges off at night (unless for an extended period).

Will turning my Bottle Cooler off at Night Save me Money?

There is much debate surrounding whether bar chillers should be switched off at night, after all, they’re not in use and cold bottles aren’t required, so surely this is increasing efficiency and saving money, right? Wrong!

Energy consumption increases significantly at the beginning of the refrigeration cycle as it works to pull down temperatures. This is when internal components, e.g. the compressor and condenser etc. are working at their hardest. While switching off fridges during the night will save energy, the energy you’ve saved plus more will be required in the morning to get the cabinet back down to temperature, making switching off the machine redundant.

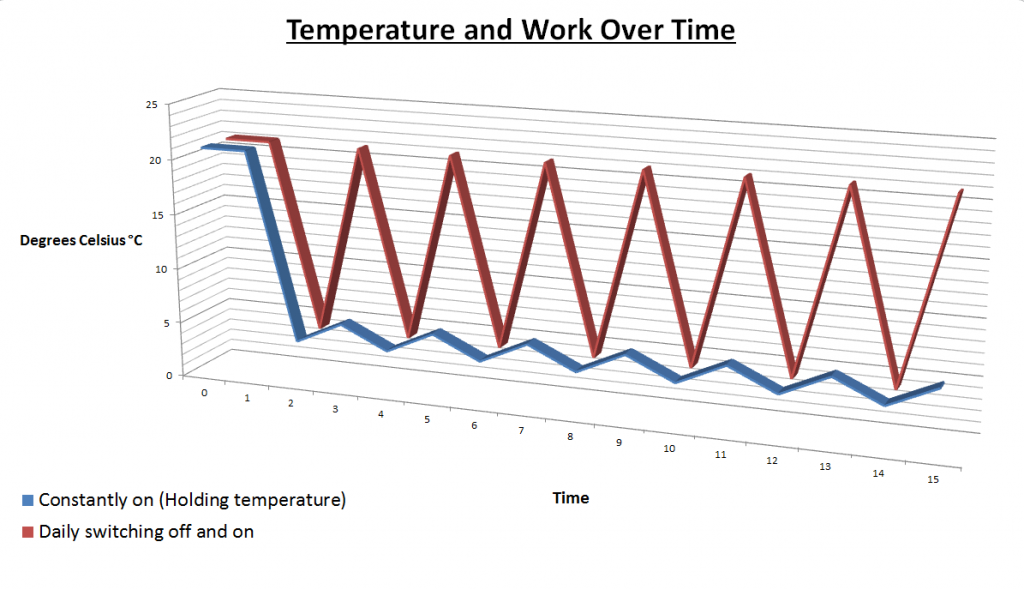

This graph is designed as a representative guide, demonstrating the estimated energy usage and the level of work components have to do in each scenario.

The blue line shows that when the cooler is left running overnight to maintain a low temperature, the overall energy usage is much lower and less strain is placed on the components, meaning lower energy bills, less chance of mechanical failure and increased expected life span.

The red line shows that whilst there may be a drop in energy usage during the night, the extra power and strain on components imposed every morning means that overall energy bills will be higher and risk of component failure greatly increased.

The majority of bar refrigeration units are designed as ‘holding’ cabinets that maintain and not continuously ‘pull down’ temperatures.

It is not recommended to repeatedly switch refrigeration on and off as unnecessary strain and pressure is placed on the coils, evaporator, compressor and condenser.

This increases the workload and can cause premature wearing and overheating of components, resulting in reduced life expectancy of the unit.

On average, it can take between 8 and 10 hours for a fully stocked fridge to reach optimum temperatures. Even if cabinets are switched on first thing in the morning, bottles will rarely have sufficiently chilled before opening, resulting in warm drinks and unhappy customers.

To read more about bottle coolers including how they work, energy consumption and tips on how to reduce environmental impact take a look at this nus pdf:

https://www.nus.org.uk/PageFiles/4888/REG-7-Bottle-Coolers.pdf

Understanding Refrigerants

Commercial bottle coolers will generally use one of three refrigerants. Before you make a decision, make sure you know the basics of each.

R134a; hydrofluorocarbon; being phased out due to environmental issues, however, is easier to service as the majority of engineers can work with it.

R600a/R290; isobutane/propane; more environmentally friendly, cheaper and more efficient, however, it is flammable and you will need a specialist engineer to carry out any service and repair work.

Choose your Finish

Choosing a finish that will complement your bar is imperative to maximising your bottle display and creating a wholly professional design. Generally, bar fridges are available with black, silver or stainless steel options, although this will depend on the manufacturer and the budget you’re working with. Each finish is capable of creating an attractive presentation for your bottled stock.

Also, consider the interior finish of the cabinet. Stainless steel or darker colours are more preferable than white plastic as white can discolour over time, potentially resulting in an unprofessional, sub-standard drinks display.

Brand, Manufacturing Quality and Price

Brand, manufacturing quality and price are all closely linked and will all bear some relation to the other. The market is flooded with choice when searching for the perfect bottle fridge. The sheer range of brands guarantees that you can find the perfect balance between size, capacity, design, build quality and budget.

![]()

![]()

Entry level brands are recommended to bridge a gap or as a short term solution. Although manufacture may not be as high quality as leading brands, models in this area of the market are perfect for businesses on a tight budget.

Mid-tier brands offer the perfect meeting point between entry and premium equipment. With greater manufacture quality and more features than entry-level brands and all for an attractive price, the middle sector of the market offers the best of both worlds.

![]()

![]()

Premium leading brands such as Gamko and Osborne should be viewed as investments that will give years of loyal service if looked after, serviced and maintained regularly. Offering increased efficiency, advanced features and specifications and enhanced cooling speed and accuracy, high quality, precision performance is guaranteed.

Bar chillers in the topmost section of the market will obviously come with a higher price tag, however, will deliver overall better build quality and more durable refrigeration components, extending the useful life of the equipment.

Take Advantage of Leasing Options and 12 Month 0% Interest-Free Credit

Where your budget won’t stretch to the brand or model you want, there are other options available rather than buying outright.

- Consider finance or leasing options, designed to help you make a sound investment while spreading the cost into smaller monthly repayments.

- 12 month 0% interest-free credit is available on Gamko bar coolers and can be a great way to get the best on the market without the large upfront cost.

Get to Grips with Bar Fridge Warranty

All back bar fridges will be supplied with some form of warranty, whether that’s parts only or parts and labour, typically for 1, 2 or 3 years, however some manufacturer’s offer up to 5 years cover.

A parts only warranty, as the name suggests, will only cover replacement parts in the event of a breakdown (due to a manufacturing fault) and does not include any labour charges (which must be covered by the user). Parts will only be dispatched once an engineer’s report has been submitted; the cost of the engineer call-out being payable by the user. A parts only warranty will not cover perishable parts such as handles, seals, runners, hinges (if any), bulbs and glass.

A parts and labour warranty will cover the cost of replacement parts (where there is a manufacturing fault) and the cost of labour to repair. If an engineer attends site and the problem is found to be user error, the user will be liable to pay the total cost.

We Suggest:

A full parts and labour warranty is always the best option, giving peace of mind that any unexpected issues due to manufacturer fault will be resolved at no extra cost.

A Word of Warning!

Regardless of the level of warranty cover supplied, regular maintenance, general care and correct use is always advised to extend longevity, improve performance and minimise potential problems. Failure to carry out essential maintenance or observe basic operational instructions given by the manufacturer can void the warranty, i.e. keeping vents clear and ensuring unobstructed airflow around the unit.

Cleaning, Servicing and Maintenance

If you want precision performance and optimum efficiency, it’s essential to carry out daily cleaning and observe regular servicing and maintenance schedules. While qualified engineers will take care of the technical side there are a few simple things that you can do to keep your bar refrigeration running in perfect working order.

1. Keep vents, condensers and compressors clean, dust free and unobstructed by giving them a wipe; alternatively a vacuum also does the job. This task should be carried out, at a minimum, monthly; ideally more regularly.

2. Ensure that there is ample airflow around the exterior of the equipment to prevent overheating of components.

3. Clean the interior of the cabinet and doors daily to eliminate any sticky surfaces caused by spilt drinks; a common problem in bars. Any build-up isn’t only unhygienic but can also cause problems such as the doors not opening/closing properly. Extra care and attention will also make your bottle display much more attractive to customers.

4. Check door seals regularly. Ill-fitting seals will let cold out and warm in, increasing operating costs and putting more strain on refrigeration systems.

5. Take any extra strain off your compressor by defrosting regularly. This will minimise the level of frost formed and reduce the amount of work the compressor has to do.

6. Annual servicing by a qualified engineer is essential and plays a major role in the performance, efficiency and longevity of your bottle cooler. Make sure you stay up to date with servicing schedules for all pieces of equipment.

Asking an Engineer

We spoke to FFD's leading refrigeration engineer, James Hancocks and asked him about the importance of servicing and maintenance of bottle coolers. He said,

“It’s essential to continue with regular servicing by a qualified engineer at least once a year on all commercial bottle coolers. In addition to this, regular maintenance and cleaning schedules should be carried out in-house. By taking care of your equipment you should be in a position to enjoy uncompromised performance and increased longevity of vital pieces of refrigeration.”

Asked about recommendations, he said

“We recommend investing in a Gamko bottle cooler; not only do they feature a copper coil condenser which is relatively maintenance free as opposed to the aluminium fin condenser seen in the majority of brands but they offer a long warranty, demonstrating the confidence that the manufacturer has in the product. If you make an investment at the start and take good care of the equipment, you will get many years of quality service in return, saving money in the long-run.”

Ask Advice

If you’re unsure about any aspect of your bottle cooler purchase or just need a second opinion before you make an investment, ask the advice of an impartial third party. If you have friends in the industry they might be able to offer some helpful suggestions, however, be careful; what works for them might not be right for you.

Alternatively, you could ask an impartial dealer for an unbiased view. The FFD sales team have over 20 years of experience in the commercial refrigeration industry and are trained to listen to customer’s needs and tailor options based on personal requirements to help every business find the perfect commercial bottle cooler.

Know what you're looking for? View our full range of commercial bottle coolers and complete any bar set-up. Alternatively, if you're searching for the perfect general purpose glass door fridge or freezer, take a look at our handy display refrigeration buying guide.

Leave a Comment

Your email address will not be published. Required fields are marked *