First invented in the late 1950’s, slush machines as we know them only really became a hit with younger generations from the 1970’s onwards. Producing a delicious ice beverage that attracted the crowds, more and more businesses began to understand the profit-making potential of these iced drinks.

As the years have passed the slush market has grown in popularity becoming a cold treat enjoyed by any generation, all year round. Continuing to go from strength to strength, the commercial slush machine is now a solid feature for many shops, supermarkets, cafes, concession stands, kiosks and snack bars.

In order to realise how your business could harness the full potential of a slushie maker it’s vital to understand how a slush or granita machine works and what you should be looking for when it comes to choosing the right one for your establishment.

This buying guide aims to explain all things slush from what it actually is and how equipment works, to the components of the machine and different features plus a few top tips and handy hints along the way.

Table of Contents

What is Slush?

Why Buy a Slush Machine?

What Can you Put in a Slushie Machine?

How Do Commercial Slush Makers Work?

Choosing a Slush Drinks Machine

Calculating the Number of Slush Servings by Tank Capacity

Carbonated Slush Machines

What Temperature Range Do Slushie Makers Operate At?

Slush Machine Placement for Optimum Performance

Are Slush Machines Noisy?

Features to Look For When Buying a Commercial Slush Machine

Powering your Slushy Machine

Regular Cleaning and Maintenance

Manufacturers and Warranties

Buy Slush Machines or Slushie Machine Rental?

What is Slush?

These iconic frozen beverages are a simple mix of water, sugar, flavour and colouring. Striking the perfect balance between a refrigerated drink and a solid ice pop the unique texture has been attracting dedicated slush lovers for years.

Usually enjoyed from a cup with the help of a straw and spoon hybrid, nothing quite beats sucking up the juice and spooning in the soft ice and with an ever-expanding choice of flavours available, the excitement that surrounds these drinks shows no sign of abating.

The cold, refreshing, taste bud bursting nature of these drinks combined with the substantial profit margin that can be made on slush has cemented them as a firm favourite with customers and businesses alike.

Considered to be an impulse buy, slush machines are typically found in a dominating position, often on countertops near tills where they are clearly visible and in direct sight of the customer.

Why Buy a Slush Machine?

Valera Granit1 Slush Machine

A commercial slush machine is a fully integral unit designed to create and dispense slush. Slushy makers can revamp your beverage offering and allow you to expand your drinks menu, all from just a single piece of equipment.

The visual impact that a frozen slushy or granita machine creates can be a massive marketing tool, really drawing customers attention and creating a focal point. What’s more, unlike refrigerated drinks dispensers that must be emptied at the end of the day and refilled the following morning, slush can be left in the machine overnight.

If considering expanding into the slushie market, you will soon notice that machines can be quite pricy and are not cheap to set-up. Don’t let this put you off the idea: remember that slush drinks can withstand a substantial mark-up so although that initial outlay may be high, you will soon reap the rewards and see a generous return on investment (ROI).

What Can you Put in a Slushie Machine?

As the name suggests, slush is the most common ingredient however these frozen beverage machines can, in some cases, offer so much more versatility. Popular uses may include cocktails, iced teas and coffees, frappuccinos, milkshakes, regular chilled juice and granita. If you’re looking to capitalise on the latest craze of fizzy or carbonated slush, you will require a separate machine.

The range of slushy tastes available is ever expanding and while this guarantees that you can accommodate all the popular flavours it also affords you the chance to think visually with regards to your display. A key feature of slush other than the distinctive texture, full flavour and obvious chilliness is the vibrancy of the colours. Make this work to your advantage from the perspective of attracting custom. By choosing contrasting colours for multiple tank models, you can really make your slush area pop.

How Do Commercial Slushie Makers Work?

To understand how slush makers work, you need to understand the different components, what each does and the part it plays in creating and dispensing slush.

Base

The base makes up the main body of the machine and houses the refrigeration system including the compressor and the condenser. It acts as the heart of the slushie maker that allows the creation of flavoured slush ice. Providing a stable support for the tank, the equipment can be levelled to ensure smooth operation.

Drip Tray

Sitting at the base of the machine, drip trays are designed to catch any stray drips or spillages, keeping surrounding surfaces clean. Drip trays are generally removeable allowing for quick emptying and cleaning when required.

Handle & Slush Dispenser Tap

Typically, equipment will have a simple pull or push handle which opens the way for the slush to flow down to the dispensing tap. Each component can be detached for easy, in-depth cleaning to maintain hygiene and food safety.

Central Cooling/Freezing Cylinder

Rather than the vertical refrigeration tube that is seen with juice dispensers, slush machines feature a horizontal cylinder. This delivers freezing temperatures evenly throughout the slush tank and to the mixture in order to create the desired results.

Stirrers

Sometimes referred to as the agitators, the stirrers are attached to the central freezing cylinder in a spiral to evenly circulate and mix the slush. All slush machines feature horizontal stirrers mixing back and forth while some models will also use a vertical stirring motion which mixes up and down.

Bowl/Tank

The bowl or tank is the clear container that houses the freezing cylinder, stirrers and slush mixture and also supports the handle and dispensing tap. Bowls are typically made of strong plastic to provide durability, ease of cleaning and decreased risk of breakage.

Slush Mixture

Although not technically an integral component of the structure of the machine, the slush mixture it is a vital ingredient. If the refrigeration system is the heart of the machine then the slush is the blood. To create the perfect consistency, it’s critical that the mixture has the correct ratio of water and sugar.

If you don’t feel ready to take the leap and create a mixture from scratch there are ready-made slushie mixes and syrups available with the correct measurement of sugar already included: all that’s required to achieve the desired results is water dilution according to manufacturer’s mix ratios.

The mixture once diluted is manually poured in to the bowls and requires manual topping up throughout the day.

So, What’s Behind the Science of Slush?

The very nature of slush goes against basic science however it somehow works. Slush machines operate at a temperature below 0°C where technically the water should form into a solid lump of ice. It is a combination of the stirring motion of the machine and the ratio of the mixture that prevents this from happening and results in the consistency that we all know and love.

The presence of sugar acts as a barrier or obstacle between the water molecules, preventing the water from bonding together into solid ice. Too much sugar in the slush mix will cause a runny, unformed end product while too little sugar will result in an overly coarse slushy drink due to larger ice crystals being formed.

The continuous movement of the stirrers also plays its part in developing the perfect slush by distributing the small ice crystals to prevent formation, bonding and solidifying. The constant circulation not only prevents total freezing but also ensures even chilling.

Choosing a Slush Drinks Machine

There are many questions that must be answered in order to whittle down the available options and find the perfect slush drink machine for your business.

How much countertop space is available?

Where will you potentially site the equipment? Do you already have free countertop space or will you need to create some? Obviously, the size of the slushie machine that you can house will depend on the space that’s available to you. The maximum footprint of the unit that you can accommodate will lead onto…

How many tanks?

The number of tanks obviously dictates the number of slush flavours you can offer. Although generally the more options given to customers the better, this may not be possible when taking into account the countertop space that you have available. The more flavours, the greater the number of tanks required and therefore the larger the dimensions and footprint of the machine.

What do you want to serve?

Slush is the most obvious answer, but some equipment doesn’t limit the possibilities to just this. Some (not all) models are also suitable for other frozen treats including iced teas, frappuccinos and milkshakes, even cocktails in some cases. The common factor between these drinks is that they all require freezing.

But don’t limit yourself there. Some manufacturers also combine the standard freezing function with the option to simply refrigerate beverages. This means you can potentially serve chilled orange juice and frozen slush all from the same piece of equipment with an easy flip of a switch as with the Blue Ice ST12X3 Triple Tank Slush Machine.

If versatility is a key factor for your business look for a model that can deliver multiple functions.

How many slush cups do you estimate serving?

You’ve determined the number of flavours you want to offer within the size footprint that your business can support and also what you actually want to serve: now you need to assess your estimated number of servings. This figure will directly influence the size and capacity of the tanks or bowls.

Capacities typically range from 5 litres to 12 litres gross. If the estimate for predicted servings falls on the low side then a smaller capacity is obviously better suited, while a high turnover will

require a larger tank. Obviously, smaller bowls can be used to serve large numbers however they will require more frequent filling and therefore demand greater manual input.

Slush serving sizes will generally range anywhere from 7 oz. (198 ml to 0 d.p.) to 20oz (568 ml to 0 d.p.). Obviously the smaller the serving the more you’ll get from your tank, the larger the serving of slush the less you’ll get from a single bowl.

We recommend to go for the higher end of your serving estimate. This ensures that as your slush venture becomes more popular and picks up pace, your equipment will still be able to keep up with demand.

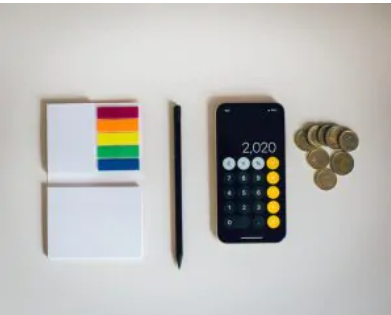

Calculating the Number of Slush Servings by Tank Capacity

By employing a simple calculation, you can work out the approximate number of servings you can expect to achieve from a single tank. This will help to determine the tank capacity you require when choosing your equipment.

1000ml. ÷ Serving Size (convert to ml.) = Number of servings per litre

Number of servings per litre × Tank capacity = How many servings you’ll get from your tank

This example shows the calculation based on 10 oz. servings from a 10 litre tank.

1000 ÷ 284ml (approx. 10 oz.) = 3.5 servings per litre

3.5 × 10 = 35 cups

Consider the cost of equipment

The cost of equipment should never be the only defining factor when choosing your slush maker however it will always bear some influence on your final choice. Always aim to get the best that your budget allows. Choosing low cost equipment will often result in sub-standard slush and a reduction in profit potential, plus a shorter expected lifespan of the machine due to lower grade materials being used during manufacture.

Commercial slush machines can range upwards from £1000 and so can take a good chunk out of any equipment budget. If buying outright isn’t an option commercial leasing options allow you to enjoy top quality equipment and the profits that go with them without the large upfront cost.

The beauty of choosing to expand into the slush market is the healthy RIO that comes with it. Slush ice drinks can be priced at anything from £1.25 to £4.50 or more depending on the size of the serving and where you are in the country. The large mark-up that slushies can demand means that your equipment will soon cover and recoup the cost of the initial investment. The number of servings taken to make back your start-up costs will be dependent on the size of the serving and the price you charge.

Take a look at this representative example of start-up costs and the amount of servings needed to cover the initial investment:

Cost of equipment: £1800

+

Cost of flavoured syrups: £200

+

Cost of sundries inc. cups, straws and lids: £100

=

Total initial outlay: £2100

It would take 1680 servings sold at £1.25 to recoup your initial outlay or 600 servings at £3.00.

Please Note: This example does not take into account the cost incurred for power consumption or VAT and is intended as an estimated guideline only. Prices of machines, syrups and sundries will vary.

Think about style

Although the basic style of any slush machine is similar there are small nuances that can make a big difference to the impact that the machine can have in your premises.

The base will generally be manufactured using a strong stainless steel, giving the rigidity and strength required to support fully loaded tanks. This stainless steel also offers protection for the refrigeration system.

Tanks or bowls will typically be constructed using a strong, often shockproof plastic to prevent or limit accidental breakage. The shape and design of the tank varies from manufacturer to manufacturer and allows for a little more individuality. Consider whether more angular designs or rounded edges would better suit the style and decor of your premises.

Carbonated Slush Machines

Alternatively, carbonated slush machines are rapidly increasing in popularity. These fizzy slush machines such as the Blue Ice T180-2 and Blue Ice T516-3 Ultra High Capacity Fizzy Slush Machines use CO2 to add an extra zing to standard slush, taking frozen carbonated beverages to the next level. Rather than a manual top-up system as with uncarbonated slush machines, carbonated alternatives require very little manual intervention. Using a bag in box syrup system that feeds directly into the machine, a direct water feed that adds the exact amount of water required for the perfect consistency and with a pressurised barrel to inject the carbon dioxide, fizzy slushies offer minimum effort and maximum profit.

What Temperature Range Do Slushie Makers Operate At?

The main characteristic of slushies is the icy texture therefore slush and granita machines must be able to operate at temperatures low enough to freeze i.e. 0°C. Commercial slush machine temperature ranges can vary anywhere from -8°C to +4°C although the optimum setting for slush is around the -3°C mark.

The time it takes for each machine to freeze is variable depending on a number of factors including:

volume of mixture in bowl

capacity of tank

number of tanks

ambient temperature in which the equipment is placed

model and manufacturer

Freeze times will generally range between 30 and 45 minutes.

Why Do Slush Machines Use Plus Temperatures When Slush Is Effectively Ice?

When slush is being formed and held in the bowls ready to serve, only minus temperatures are used to maintain the optimum consistency. Plus temperatures are employed when the machine is switched to stand-by or night mode or if the unit has the option to hold refrigerated beverages where chilling is required without freezing.

Slush Machine Placement for Optimum Performance

As with all commercial refrigeration, correct placement is vital to ensure the performance, efficiency and longevity of the equipment. If positioned in areas where the ambient temperature is too high it will lead to inefficient operation with a greater risk of reduced quality slush and longer production times.

Sufficient ventilation and airflow around the unit particularly around the refrigeration system and vents in the base is essential. Aim to leave between 15cm and 20cm air gap on all sides.

Refrigeration manufacturers may award equipment a climate class. This tells you the maximum ambient temperatures that the machine should be operated in. Where no climate class is given always check the manufacturer instruction manual and follow their recommendations.

Are Slush Machines Noisy?

All refrigeration will produce some noise as the system works and thermostats adjust temperatures. This can cause a clicking noise and is in most cases completely normal. The majority of commercial slushed ice machines will operate at levels lower than 70dB. Bearing in mind that a normal conversation is around 60dB, this shouldn’t cause too much impact on your premises or the comfort of your customers.

Features to Look For When Buying a Commercial Slush Machine

There are plenty of features that you should think about when choosing your slush machine. These are just some of the areas we suggest you consider before making your final decision.

- Slush dispenser handle and tap

It may seem like a basic feature but always consider the durability and comfort of the dispensing handle and tap. These will be in frequent use and so must be strong and sturdy as well as comfortable to use.

- Measure gauges

Situated on the side of the tank these marks give a quick reference to the quantity of mixture within the bowl. Levels should always be kept within the minimum and maximum lines.

- Lights

Many slush drinks machines are now designed with lights as standard. This ensures that your slush really draws customers attention and achieves maximum visual impact to boost sales.

Blue Ice ST12X2 Slush Machine

Slush settings

Some models will have up to 4 different settings, such as the Blue Ice ST12X2 Twin Bowl Slush Machine to allow a variety of consistencies to be achieved from very soft to thick. Other units may have the choice of refrigeration or freeze modes, being able to switch between slush mode and refrigerated beverage mode. When in a refrigerated drink setting, a gentle defrost occurs.

Adjustable feet

A standard feature on many forms of commercial refrigeration, adjustable feet ensure that equipment is levelled, secure and stable even on uneven surfaces.

Waterproof switches

As slush machines deal with large volumes of liquid and require a power supply, waterproof switches are ideal from a safety point of view.

Drip tray

Not only providing a sturdy platform on which to place cups during dispensing, drip trays also help to maintain a clean, hygienic work area.

Bowl/TankOther than the capacity and style of the slush tank you should also consider the thickness of the plastic. This will determine how well insulated it is, therefore can influence the efficiency and freeze times of slush products.

Stand by function/night mode

The stand-by function or night mode can keep slush fresh up to approx. 14 days within the tank. This eliminates the need to empty, clean and refreeze product at the end of every day. Not only does it save time and manual input, but also reduces potential waste. A gentle defrost will occur when using this function to prevent formation of any clumps of ice.

Slush can be left in the machine overnight, however switching to a refrigerated night mode or energy saving mode as seen with the Blue Ice ST12X2 Slush Machine is recommended to prevent excessive ice formation and to conserve energy.

Branding

What better way to promote your slushies than by branding the very equipment that is displaying them? Not all manufacturers offer the chance to brand machines so if this is something you’re interested in, be sure to investigate options before buying.

Powering your Slushy Machine

Slushy makers don’t require large amounts of power to operate and will run with a 13A standard three pin plug. It is always advised to plug directly into a main socket and not an extension cable.

Regular Cleaning and Maintenance

Slush and granita are considered to be food stuffs and so machines are subject to the same regulations and food safety standards. They should therefore be treated as any other food storage or production equipment.

Slush equipment can harbour bacteria, just as any other units used to produce food or drink for public consumption and so must be regularly cleaned. You should always follow manufacturer’s instructions however typically it is suggested that every 1 – 2 weeks is sufficient or more regularly if required. Vents and filters should be cleaned approximately every 6 weeks.

Cleaning Checklist

The following steps are meant as a general guide however may differ between model and manufacturer.

- Unplug the machine

- Remove the tank cover

- Remove the spiral mixer from the central cylinder

- Carefully remove any seals

- Detach the dispensing handle and tap from the cover (if possible)

- Remove drip tray and empty

- Clean all components and surfaces with warm water and mild detergent

- Sanitise accordingly

- Wipe vents with a cloth or vacuum using a soft attachment to remove any dust or debris

- Wipe and thoroughly dry before reassembling

Manufacturers and Warranties

Slush is a massive market with many quality manufacturers bringing equipment to the market. We recommend:

Blue Ice

Leaders in the slush and ice cream market, Blue Ice are renowned for quality and performance. Not only do they deliver attractive slush machines capable of producing high quality slush, they can also offer equipment installation, a starter pack with every machine purchase and training on operation, cleaning and maintenance by their team of fully certified engineers.

Interlevin

A trusted manufacturer and supplier for all aspects of commercial refrigeration Interlevin are a well recognised name within the industry. Formed in 1967, they have a wealth of knowledge and experience behind them to guarantee quality equipment at reasonable prices.

Valera

having built a strong reputation since its inception in 1993, Valera are dedicated to providing “Quality Products backed by Quality Service” throughout their range of commercial refrigeration.

As with all commercial equipment, industrial slush machines need to be strong and durable to withstand tough commercial conditions and provide longevity, therefore deliver value for money. The typical stainless steel and plastic construction is coupled with durable motors and refrigeration systems that can guarantee performance and efficiency year after year.

To back up the slush equipment, each manufacturer that we supply includes warranty cover as standard. This can range from a 1 year full warranty that includes parts and labour cover to a 2 year parts only warranty with the option to purchase additional labour cover of 1 or 2 years if required.

Buy Slush Machines or Slushie Machine Rental?

There are companies that supply slush machine rentals however the potential profit margin that can be made from slushie drinks often means it usually makes more financial sense to purchase equipment outright.

Commercial Leasing with FFD

Need a hand investing in the right commercial slush machine? We understand that a large initial outlay to purchase quality equipment just isn’t an option for some businesses. In order to ensure that every business can benefit from the best we offer a commercial leasing option on all commercial refrigeration orders exceeding £1000 exc. VAT. This means your business can enjoy the popularity and profits that come with a commercial slush maker whilst spreading the cost into smaller, more manageable monthly repayments.

Getting involved in the slush market can revolutionise a business and create a great new stream of revenue for those looking to expand. By understanding what you’re looking for when investing in a slush machine and making an informed buying choice you will soon be enjoying boosted profits and happy customers.

Leave a Comment

Your email address will not be published. Required fields are marked *